CNC press brake is an important equipment in sheet metal processing, and its working accuracy directly affects the bending accuracy of the workpiece. Why add a compensation system to the CNC press brake during the workpiece bending process, as the maximum force is exerted on both ends of the slider and the reaction force during sheet bending causes concave deformation on the lower surface of the slider.

Why does the CNC press brake need to add a compensation system

In order to eliminate the adverse effects of slider deformation, it is necessary to compensate for the deflection deformation of the slider. The usual compensation methods include hydraulic compensation and mechanical compensation, both of which generate upward elastic deformation in the middle of the Compensation workbench to offset the deformation of the machine tool slider, ensure the accuracy of the machining joint surface, and improve the accuracy of the workpiece. At present, major foreign machine tool manufacturers use mechanical compensation devices; Domestic manufacturers will choose appropriate compensation methods based on the actual situation.

Introduction to Two Compensation Methods

Hydraulic compensation method

The hydraulic automatic deflection compensation mechanism of the worktable is composed of a set of oil cylinders installed in the lower worktable. The position and size of each compensation cylinder are designed based on the deflection compensation curve of the slider and the finite element analysis of the worktable. Hydraulic compensation is achieved through the relative displacement between the front, middle, and rear three vertical plates to compensate for the protrusion of the neutral plate. Its principle is to achieve protrusion through the elastic deformation of the steel plate itself, So its compensation amount can be adjusted within the elastic range of the workbench.

Mechanical compensation method

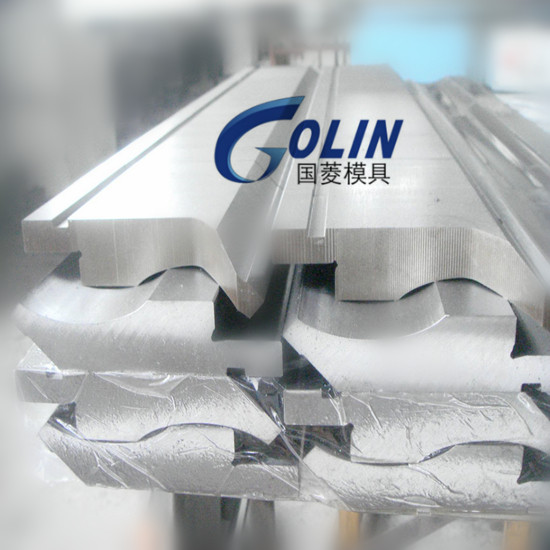

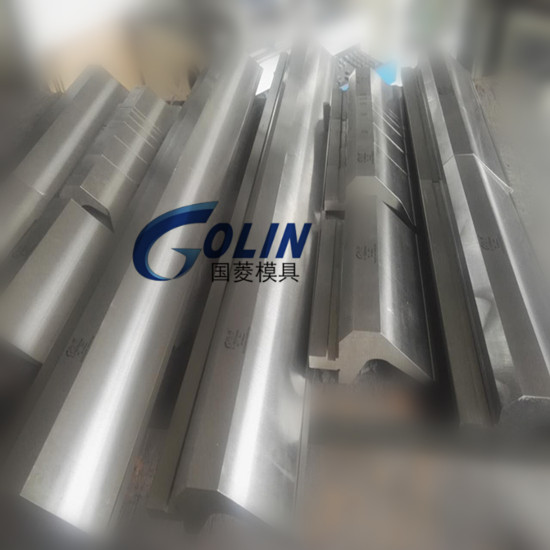

Mechanical compensation is composed of a set of convex wedge blocks with inclined surfaces, each of which is designed based on the deflection curve of the slider and worktable finite element analysis. The CNC system calculates the required compensation amount based on the magnitude of the load force during the bending of the workpiece (which will cause deflection deformation of the slider and worktable vertical plate), automatically controls the relative movement of the protruding wedge block, and effectively compensates for the deflection deformation caused by the slider and worktable vertical plate. The ideal bending workpiece mechanical deflection compensation is achieved by controlling the position to achieve "pre protrusion", A set of wedges forms a curve in the length direction of the workbench that matches the actual deflection, ensuring that the gap between the upper and lower molds is consistent during bending, and ensuring that the angle of the bent workpiece in the length direction is consistent.

Comparison of Two Compensation Methods

The advantages of hydraulic compensation:

As time goes by, hydraulic compensation does not have any wear issues, while mechanical compensation screws, wedge-shaped blocks, etc. will experience wear over time.

Hydraulic compensation takes up less space, while mechanical compensation takes up more free space in both height and width directions.

When using hydraulic compensation, the plate cannot be displaced because the lower workbench is in contact with the ground of the bent plate as a whole, and the positioning of the stop finger is very stable when it contacts the "clamping point" of the plate horizontally. Mechanical compensation only takes effect after bending, and there is a possibility of unpredictable errors.

Hydraulic compensation can also be adjusted when the workpiece is not removed, which is impossible in mechanical compensation.

The advantages of mechanical compensation:

Mechanical compensation has long-lasting stability and reduces the difficulty and frequency of hydraulic compensation maintenance (such as oil leakage caused by seal ring damage), and is maintenance free during the service life of the machine tool.

Mechanical compensation, due to the large number of compensation points, can achieve precise deflection compensation throughout the entire length of the workbench, making it easier for the press brake to achieve linear compensation when bending workpieces during operation, and improving the bending effect of workpieces.

Mechanical compensation is the use of a potential ruler to measure the position of the return signal, which serves as a CNC axis to achieve digital control and make the compensation value more accurate.

Problems encountered when using CNC press brake

When we use the CNC press brake to work, there is a high possibility of some error problems. At this time, we need to pay attention and check immediately if there are any problems. The first step of inspection is to check if there is any wear or damage to the mold currently used by the press brake. If this is the cause of the error, then replace the mold.

However, during the inspection process, if no damage is found, the second step is to check the balance between the slider and the workbench. If the site cannot meet the usage requirements, adjustments must be made according to relevant standards to ensure that this parallelism can be maintained within the standard range.

If there is still a certain degree of error in the angle of the workpiece, it may not be due to the mold or parallelism, but it may be due to the hydraulic system of the equipment, where the balance mechanism does not ensure that the pressure oil evenly enters the left and right cylinders, and adjustment is needed.

At this point, it is necessary to adjust the working mode of the press brake to the "jog adjustment" state. Remove the mold or other accessories from the equipment, so that the slider can stay on the mechanical block. Then, adjust the pressure gauge correctly by compressing the dial gauge head of the press brake by 3-4 millimeters, stepping on the foot pedal to increase the system pressure. When the press brake system is pressurized or unloaded, Check the clockwise deviation of the dial gauge. If it reaches the specified value, the operation can be stopped. Of course, in addition to the above methods, it should be emphasized that the press brake must be well maintained to maximize its advantages in use.